Design

We perform power calculations and simulations to optimize the power draw for maximum throughput. These calculations are regularly performed for different applications.

We specialize in, and offer the following services to support our customers:

We perform power calculations and simulations to optimize the power draw for maximum throughput. These calculations are regularly performed for different applications.

We specialize in, and offer the following services to support our customers:

Product Design

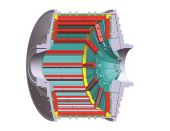

- Study of existing mill liner designs to overcome liner issues for both rubber and steel lined mills to improve mill availability and mill throughput.

- Study of slurry flow from SAG/AG mills to improve pulp lifter and grate wear.

- We perform power calculations for maximum power draw for Ball Mill liners for maximum throughput.

Process Review

- Study of slurry flow from SAG/AG mills for slurry pool or slurry flow back issues for mill throughput improvement.

- Study of slurry flow from grates to improve the grate wear life.

- We simulate and study the material trajectories to determine charge motion inside the mill to improve material grind quality, liner life and throughput.

Installation & after sales support

- We have trained professionals to provide supervision of mill liner installation.

- We also have trained professionals who can study your existing mill liner issues and offer solutions for efficient mill operation.

- We regularly monitor mill liner wear by measuring the worn liners to plan shut downs for liner change.

Lunch & Learn

- We have trained professionals who can provide information to your group about mill liner types, mill liner installation, mill liner issues, mill liner changes and scheduling.

Mining Custom Solutions

We have a team of trained Mining personnel to study your specific need and offer you custom solutions:

- If you have throughput problems; or

- If you have grinding issues; or

- If you have to shut down your mill for frequent liner maintenance; or

- If you want to improve mill liner life; or

- If your SAG / AG mill grates are wearing out too fast; or

- If you have old mills with weakened shells or head; or

- If you have any other concerns

REQUEST FOR CONTACT

Looking for more information. Help us help you by filling out our simple online contact form.

Request